-

MINIMALSThe MINIMALS - Micro and Nano Integrated Manufacturing Lower Saxony project aims to improve the infrastructure for the development of quantum technologies in Lower Saxony. The project is co-financed by the European Union and invests in cutting-edge technologies to establish advanced production processes for quantum systems. It plans to integrate an 8-inch compatible lithography line, a confocal sputtering system and an ultrashort pulse laser system into the clean room to support the production of atomic vapor cells, which are crucial for modern quantum systems. MINIMALS aims to develop a technological “core facility” in the Hannover/Braunschweig region that will promote both basic research and sustainable economic growth in Europe, with a particular focus on quantum technology and the microelectronics industry. The project supports the United Nations Sustainable Development Goals by developing innovative solutions to currently intractable challenges. This is the second grant from the European Regional Development Fund (ERDF) that the IMPT has received, following support for the HARD project in 2022.Year: 2024Duration: 2024-2027

![]()

![]()

-

FlexEnergy4UThe FlexEnergy4U project is a cooperation between Ladon Energy GmbH and the IMPT, funded by the NBank. The main aim of the project is to break down the energy consumption of private households in detail and make this data usable for flexible tariff models and other applications. Ladon Energy GmbH is working on the further development of its sensor, while the IMPT is responsible for processing and evaluating the data. For this purpose, neural networks are used that run directly on the sensor to disaggregate the energy data. This enables energy consumption to be precisely allocated to individual appliances and allows future consumption to be tracked and predicted. In combination with energy management systems, users can make their energy use more flexible, increase energy efficiency and reduce energy costs. The flexibilization of consumers also supports grid stability in view of the increasing volatility of electricity production from renewable energies.Year: 2025Funding: NBankDuration: 2025-2028

-

AeroQGravIn flight gravimetry, gravitational acceleration is identified as the difference between a gravitational acceleration measurement by a gravimeter on the one hand and the inertial acceleration of the flight path relative to inertial space on the other, which is determined via satellite navigation or alternative methods, for example. Thanks to flight gravimetry, the Earth's gravitational field can be measured efficiently and over a large area, which has always provided key information for the geosciences, but also for the search for raw material deposits. In geology and geotectonics, gravimetry is used to identify subsurface density anomalies, in geodesy to define reference surfaces for national height reference systems, in oceanography to determine ocean currents or to record changes in mass distribution on Earth, triggered in no small part by changes in our climate. As part of this sub-project of the AeroQGrav project, the technology of quantum gravimetry is to be adapted to the needs of flight gravimetry. A new type of quantum flight gravimeter - the AeroQGrav - is to be developed as part of the project and tested in several test campaigns in flight (and possibly also on water if available). The aim is to demonstrate a higher resolution and long-term stability in the measurement of gravitational acceleration. The IMPT is involved in the development and production of the atom chip system for AeroQGrav. This system will be made available at an early stage. In parallel, the atom chip technology will be evaluated by the IMPT through extensive qualification measures and long-term tests, both in the laboratory and in practical applications, in order to prepare the atom chip system for commercialization. Process plans and production are being adapted in order to complete the transition from prototype production to robust standard components.Year: 2024Funding: VDI / BMBFDuration: 01.12.2022-30.11.2027

![]()

![]()

-

Q-GALAWhat current activities in the field of quantum technology have in common is that they are usually laboratory-based setups. In addition to the spatial and financial aspects, these systems require corresponding expertise on the user side for operation. They are therefore primarily suitable for basic research and scientific-technical service tasks, such as those carried out at metrology institutes. The Q-GALA project will develop a miniaturized, glass-based quantum system platform based on the example of the atomic interferometer. This platform represents the first step towards a miniaturized quantum system (MQS), which is highly relevant for any application in the field of quantum technology. At the same time, it also paves the way for economical series production, making quantum technology accessible to a wide range of users. The use of glass as a transparent substrate opens up completely new design possibilities, such as the rear approach of the beams. In addition, glass is an electrical insulator in the targeted temperature ranges, which suppresses eddy currents and also avoids the use of additional, potentially faulty insulation layers. In addition to the functional properties already offered by the silicon-based system, the photonics part is added here by actively utilizing the optical properties of glass.Year: 2024Funding: Zukunftscluster / Projektträger JülichDuration: 01.03.2023-28.02.2026

![]()

![]()

-

CARIOQA-GEThe goal of this project is an investigation to define a pathfinder mission for satellite-based, inertial-sensitive atomic interferometry (CARIOQA-GE - Cold Atom Rubidium Interferometer in Orbit for Quantum Accelerometry). The aim is to determine the most advantageous scenarios and requirements for a Pathfinder mission, taking into account financial and technical constraints. The study draws on the unique expertise of LUH scientists in the development of miniaturized quantum systems for applications in microgravity, which is based on successful micro-gravity campaigns, from experiments in the drop tower to sounding rockets and the ISS. Using a simulation program specially developed for satellite-based atom interferometry, the scenario for a Pathfinder mission and evaluation of its results will be further developed with regard to scientific added value for the Earth observation community. In addition, a new atom chip design is to be developed that is suitable for a quantum space gravimetry mission. The main task of the IMPT is the development and detailed evaluation of the manufactured atom chip systems, the identification of potential weak points and the subsequent revision in cooperation with the Institute of Quantum Optics at LUH. Since the atom chip systems themselves are operated under UHV conditions, microscopic and certain metrological analysis methods pose a challenge. For this reason, the IMPT will develop a test chip equipped with sensors to monitor internal and external influences during operation. This test SC chip will replace the SC chip for evaluation tests. On the basis of the findings obtained, both limit values for operation can be determined and necessary revisions can be derived. An initial atom chip system, which will be developed and manufactured at the start of the project, will serve as the basis for these tests.Year: 2024Funding: DLR / BMBFDuration: 01.10.2022-30.09.2025

-

CARIOQA-PMPCARIOQA-PMP (Cold Atom Rubidium Interferometer in Orbit for Quantum Accelerometry - Pathfinder Mission Preparation) aims to develop a new technology to be deployed in space within the next decade: Quantum Accelerometers. This technology will be used for satellite-based geoscience to monitor climate change and thus support the development of mitigation and adaptation measures. The technology developed within the CARIOQA-PMP will be tested during a space mission: the Quantum Pathfinder Mission. In addition to developing a technical model for the space mission instrument and developing, improving and testing critical technologies, CARIOQA-PMP will also produce a technical and programmatic roadmap for quantum space gravity missions. This roadmap will be shared and validated by the European stakeholders. It will ensure that the results of the project have maximum impact through its harmonization with the European programmatic framework. CARIOQA-PMP brings together leading stakeholders from five EU countries. These include experts in satellite instrument development (Airbus Defence and Space, Exail, TELETEL, LEONARDO), quantum sensing (LUH, SYRTE, LP2N, LCAR, ONERA, IESL/FORTH), space geodesy, geosciences and gravity field data users (LUH, TUM, POLIMI, DTU) as well as experts in impact maximization and impact assessment (PRAXI Network/FORTH, G.A.C. Group). The preparation of the pathfinder mission is being coordinated by the French and German space agencies CNES and DLR under the leadership of CNES.Year: 2024Funding: EU, Horizon Europe (HORIZON)Duration: 12.2022-03.2026

![]()

![]()

-

CRC TRR 375 – A04: Integrated component monitoring of highly loaded hybrid porous componentsThe overarching scientific objective of the CRC TRR 375 is to establish a new class of materials: multifunctional high-performance components made of hybrid porous (HyPo) materials. These HyPo-components will enhance the energy efficiency and performance of a wide range of products, ensure product safety through component-integrated sensor technology and facilitate data acquisition in the context of digitalization. The challenges lie in the gradient of material properties, the stability of high-temperature sensors and the complex interdepence of residual stress state, relaxation and fatigue behavior. In this context, the IMPT is working in sub-project A04 on component-integrated polymer-free thin-film sensors that are used for data acquisition during the manufacturing and use phase.Year: 2024Funding: DFGDuration: 2024 - 2027

![]()

![]()

-

SELFLEDThe investigation of single cells in synthetic microenvironments can provide enormous information about cell properties, cell interactions and interactions with active substances. The large amount of time, personnel and material required generally restricts such investigations to the scale of microtiter plates, i.e. plates with typically 96 and up to 1536 micron wells. Fluorescence microscopy is used here as an essential analysis tool. The cells are stained with fluorophores that fluoresce when irradiated with certain wavelengths. However, the constant irradiation of the cells leads to photobleaching and photooxidative stress and thus to falsified test results due to degrading fluorescence and reduced viability of the cells. The aim of the SELFLED research project is to develop a novel illumination unit for fluorescence microscopy that enables controlled, selective and monitorable irradiation of any microenvironment, thus making photobleaching and photooxidative stress controllable and reducing them without restricting the performance of experiments. To this end, microLEDs and micro-optics embossed in glass are to be combined in a highly integrated package adapted to the specific conditions of the micro-cells. A laser-assisted embossing process is being investigated for the micro-optics, which enables the automated production of application-specific microlens arrays at wafer level, for example.Year: 2024Funding: BMBFDuration: 2024 - 2026

![]()

![]()

-

InnoVaQThe development of quantum sensors suitable for everyday use requires a high degree of miniaturization and integration of the vacuum system. In the InnoVaQ (Innovative Vacuum Technology for Quantum Sensors) research project, technologies are being developed that together allow a highly compact ultra-high vacuum setup to be realized for a strontium atom-based quantum sensor. In the long term, the increasing miniaturization in the field of quantum sensor technology not only leads to a reduction in the size of the housing, but also necessitates a vacuum periphery of the corresponding size. Thus, a miniaturized pumping technique is needed to develop compact and transportable quantum sensing technology. In this context, the IMPT is developing a combined device in cooperation with LPKF®, which is similar to an ion getter pump in terms of its functional principle. The core component is a magnet-free field emitter which does not influence the measurements of the quantum system. Two approaches are being pursued for the technical implementation of the emitter, firstly a silicon-based approach (IMPT) and secondly a glass-based approach manufactured using LIDE technology (LPKF®). The pumping technology to be realized by IMPT is based on micro-engineered field emitters in the form of tips fabricated by a cut-off grinding process. This technology has been patented by Leibniz Universität Hannover and enables the production of highly integrable emitter tips that act as electron sources for ionization in miniaturized ion getter pumps. Importantly, in the developed vacuum system, the pressure in the ultra-high vacuum (UVH) region is 10-8 to 10-11 mbar. To reach this pressure, a combination of backing pumps and high vacuum pumps is needed, since single-stage pumping from atmospheric pressure to UHV is not possible. After reaching the target pressure, the miniaturized vacuum pump developed in this project should be able to maintain and measure the pressure.Year: 2022Funding: Bundesministerium für Bildung und ForschungDuration: 01.01.2022-30.06.2025

-

SFB 1368 C03 – Investigation of tribological systems for tool coatings in an inert atmosphereIn the Collaborative Research Center 1368 "Oxygen-free production", processes and mechanisms in manufacturing technology processes are investigated that are carried out in an oxygen-free atmosphere. In subproject C03, the IMPT is investigating the influence of the atmosphere on tribological systems for the subsequent development of tool coatings in an inert atmosphere. Important aspects include the identification and quantification of fundamental relationships of wear processes in silane-doped atmospheres, diffusion and adhesion effects and the investigation of possible novel alloy formations at the interfaces.Year: 2020Funding: DFGDuration: 2020 - 2027

![]()

![]() © IMPT

© IMPT

-

ISiG – Integrated Sensors for intelligent Large-Diameter BearingsIn the context of digitization, the acquisition of measurement data plays a central role in the use of large components. For rolling bearings, the application of conventional sensors is hardly possible in situ due to the dimensions, so that the "ISiG" project addresses the use of various customized thin-film sensors. They will be produced directly on the machine element through coating processes that produces integrated, component inherent sensors on the measurement object. In cooperation with the Institute of Machine Design and Tribology (IMKT), the first step is to simulate the mechanical loads that occur and to derive the design of the sensor nodes. The high surface pressure, slipping and wear place the highest requirements on the sensor technology, which is why the development of redundant sensor systems by means of intelligent sensor data fusion represents a primary goal.Year: 2021Funding: DFGDuration: 2021-2025

![]()

![]()

-

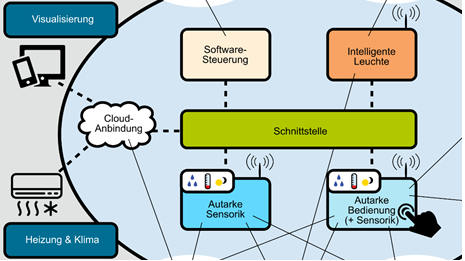

ENDEMAR (Energy Saving by Use of Multiple Autarkic Control Sensor Systems)Intelligent Energy Flow – Reduction of Energy Consumption through Maintenance Free Sensors in Buildings and Accommodations The project is funded by the German Federal Ministry for Economic Affairs and Energy. The aim is to intelligently control and reduce the energy consumption within factory buildings and warehouses. The function will be demonstrated with LED light sources, but remains open for other energy users such as air-conditioning systems or heatings. The control is based on intelligent, maintenance free autarkic sensors with passive and active control functions and ultra-low energy consumption. Within the project three industrial companies and three research facilities are collaborating. The IMPT is supporting by developing a suitable energy-optimized energy-harvester for powering of autarkic, maintenance free control panels.Led by: Folke DenckerYear: 2021Funding: German Federal Ministry for Economic Affairs and EnergyDuration: 2021-2025

![]()

![]()

-

QGyro+ (Development of a compact experimental platform of a gyro-stabilized quantum navigation sensor)In the research project QGyro+, high-precision quantum inertial sensors will be developed and tested to support conventional inertial navigation sensors. Highly accurate and non-manipulable navigation systems, which can also be used when conventional GPS is not available, are particularly important for aviation, space and shipping as well as autonomous driving. The central goal of the project is to develop a six-axis quantum inertial navigation sensor. With this device, drift-free and highly accurate quantum inertial sensors are to be tested for the first time for use in autonomous navigation in order to open the way to new fields of application. In the course of the project, this sensor will be set up and used as a compact experimental platform (QINS experimental platform). The IMPT will play a key role in this by driving forward the miniaturization of various system components. To increase the degree of integration, so-called atom chips, as a component of the magneto-optical trap, with extended mirror reference surfaces are used, which are developed and manufactured at the IMPT. In addition, the IMPT is researching a wide range of technologies, in particular to miniaturize the required ultra-high vacuum system and the associated vacuum periphery. A promising approach to maintain the ultra-high vacuum (UHV) is the active pumping of the system as well as the corresponding pressure measurement by means of micro-engineered, magnetic field-free ion getter pumps based on field emitter arrays. The field emitter arrays developed at IMPT consist of hundreds of thousands of nanoscale field emitters, each with concentric extraction electrodes. These electrode sources provide free electrons for efficient residual gas ionization, so that the ionized residual gas atoms can subsequently be bonded to a functionalized ion collector. In combination with newly developed vacuum chamber concepts, the vision of a UHV microchamber with integrated pump and measurement technology and atom chip technology is to be realized in the long term.Led by: Alexander Kassner, M.Sc.Year: 2021Funding: DLRDuration: 01.01.2021 - 01.03.2026

![]()

![]()

-

Quantum Valley Lower SaxonyThe overall goal of the QVLS is to build a 50 qubit quantum computer. The IMPT is part of this excellent research network with access to unique infrastructure of the whole consortium. The team has excellent national and international networks and participates (besides QVLS-Q1) in important collaborations, including the Cluster of Excellence "QuantumFrontiers". The IMPT is part of several teams. In QVLS T2.4, building on our expertise in atom chip fabrication, we are addressing the design and construction of an atom chip with the possibility of depositing a glass package on the surface of the atom chip and encapsulating it. In this course, we are evaluating joining techniques with respect to hermeticity. Furthermore, in a novel implementation of these atom chips with a grating-based magneto-optical trap, we aim to integrate an optical grating into the atom chip surface. In QVLS T3.1, we are developing processes and methods to connect an ion trap chip together with the associated quantum control components (CMOS electronic chip, active photonic chip, passive optical interposer). This includes all connections to the outside world (cables, fibers). This ion trap packaging solution will be based on 3D hybrid integration techniques to enable stacking and bonding of dies from ceramic, glass and silicon substrates at wafer level. In QVLS T3.3, as part of the miniaturization of the vacuum system and the peripherals necessary for the operation of the quantum sensor, we are addressing the evaluation of joining glass to titanium and joining components under UHV conditions (themo-compressive and anodic). Furthermore, we are involved in the development of a pumping technique, which will initially be based on non-evaporable getter materials (NEG). Furthermore, we are developing and characterizing a platform for chip-based atomic sources for use in quantum sensors.Year: 2021Funding: VolkswagenStiftung & Niedersächsisches Ministerium für Wissenschaft und KulturDuration: 2021 - 2025

![]()

![]()

-

Gallium Nitride for Advanced Power (GaN4AP)The GaN for Advanced Power (GaN4AP) project is an international collaborative project funded by the EU's ECSEL initiative. Worldwide, the number of hybrid and electric cars is growing steadily. This is accompanied by a greater need for high-performance electronics in charging technology. In order to meet the increasing demand, high power transformers based on Galium Nitride will be realized in this project with partners from Italy, Czech Republic, France and Germany. IMPT is participating in the project by manufacturing transformers and inductors in planar technology on Printed Circuit Boards (PCBs) and Molded Interconnect Devices (MID). These are essential for driving and filtering the electrical signal. The planar structure meets the demands for miniaturization of electrical systems and simultaneous increase in performance.Year: 2021Funding: ECSEL (EU)Duration: 2021 - 2025

![]()

![]()

-

PhoenixDThe Cluster of Excellence PhoenixD deals with the topic of realising optical precision devices quickly and cost-effectively using additive manufacturing. This vision unites researchers from the faculties of mechanical engineering, physics, electrical engineering, computer science and chemistry at Leibniz Universität Hannover and TU-Braunschweig. The researchers are working together on the simulation, production and application of optical systems. The systems currently based on glass are complex, usually manufactured by hand and sometimes require large installation spaces. The cooperation of the different departments is now to develop a digital manufacturing system with which individualised optical products can be realised.Year: 2019Funding: DFGDuration: 2019 - 2025

![]()

![]()

-

Quantum FrontiersThe Cluster of Excellence QuantumFrontiers combines the research strengths of Leibniz Universität Hannover, TU Braunschweig and the Physikalisch-Technische Bundesanstalt in Braunschweig with the aim of developing new measurement concepts and sensor topologies based on photonic systems, dedicated semiconductor systems, nanostructures, quantum-manipulated atomic and molecular ensembles, and even macroscopic objects. The IMPT focuses mainly on atomic interferometry and is involved with two research groups.Year: 2019Funding: DFGDuration: 2019 - 2025

![]()

![]()

-

QCHIPThe Institute of Microproduction Technology (IMPT) develops so-called atom chips as components of magneto-optical traps for compact matter wave interferometers. In combination with sophisticated laser cooling, these atom chips generate magnetic field configurations to trap and cool atoms by exploiting the Zeeman effect. This represents the first step in creating a bose-einstein condensate that serves as a test mass for interferometry. In order to use such high-precision matter-wave interferometers in the field or on board satellites, miniaturization will be pursued. The number of lasers and electronics required for cooling can be reduced by patterning the surfaces of atomic chips with optical gratings. By cleverly exploiting diffraction effects, operation can thus be achieved with just one laser.Year: 2019Funding: BMWiDuration: 2019 - 2026

![]()

![]()