Industry 4.0

-

SFB 653 – L3 – Reading and Writing of Magnetically-Saved DataWithin the framework of the Sonderforschungsbereich (SFB) 653 “Gentelligente Components in a Life Cycle” in the subproject, L3, a method for magnetic storage of data directly on the surface of magnetic components in an industrial production environment is researched at the IMPT. With this concept, the data is stored magnetically with an inductive, magnetic write head. For the readout of data, a method that is based on the magneto-optic Kerr effect is used.Year: 2011Funding: German Research FoundationDuration: 2005 - 2017

![]()

![]()

-

SFB 653 – S1 – Modular, Multifunctional MicrosensorsThe subproject S1, deals with the development of modular, multifunctional microsensors at the IMPT that serve to gather the use, maintenance, and recycling-relevant data throughout the entire life cycle of a component.Year: 2011Funding: German Research FoundationDuration: 2005 - 2017

![]()

![]()

-

SFB 653-T05: Process and Tool System for the Application and Integration of Substrate-Free Modular Micro SensorsThe main goal of the transfer project is the transfer of substrate-free sensor technology in a production-oriented environment that was previously developed in the subproject, S1. With this aim, the previous results of basic research in an industry-standard application and its suitability will be evaluated.Year: 2014Funding: German Research FoundationDuration: 2013-2016

![]()

![]()

Medizintechnik

-

TR37 – B5 – Magnetic Polymer-NanoparticleFrom the University of Rostock Clinic and Health Care Center for Cardiac Surgery and the Institute for Micro Production Technology (IMPT) at Leibniz Universität Hannover, new methods were developed for which new applications and research possibilities in medical engineering were made possible by selective manipulation of magnetic nanoparticles.Year: 2011Funding: German Research FoundationDuration: 2007 - 2011

![]()

![]()

[uncategorized]

-

MicroMillMicro-milling is increasingly finding applications due to advancing developments in micro-tool manufacturing. Structuring a workpiece with geometries on a micrometer scale is possible thanks to tools with ever smaller diameters. However, these are costly to manufacture. Each milling tool must be made from solid material and undergo time-intensive grinding. This is then reflected in the price of the tools. The micro milling tools to be produced in this project are to be manufactured from silicon carbide in a batch production process, so that several hundred milling heads can be produced per time. A dry etching process will be used to pattern the milling heads, and its process parameters must be evaluated for the most anisotropic etching possible at high etch rates. Since the milling tool is produced in two parts and consists of a milling head and tool shank, an ideal joining method is sought with which both parts can be reliably joined. For this purpose, different adhesives and chemical as well as mechanical surface treatments are tested on the surfaces to be joined. The resulting adhesive strength of the two tool parts will be investigated. Furthermore, a very precise assembly technique must be developed so that the milling head can be centered on the tool shank. Otherwise, among other things, inaccuracies in the shape of the workpieces may occur. The manufacturing process will then be industrialized with the project partner Reißfelder Profilschleifen GmbH and the application limits of the milling tools will be tested on various materials with industrial benefits, such as copper or steel. The end result should be small micro milling tools made of silicon carbide, which can be used for machining in various areas, such as medical technology, and can be produced on an industrial scale.Year: 2021Funding: Förderprogramm ZIM (Zentrales Innovationsprogramm Mittelstand) des Bundesministeriums für Wirtschaft und Energie (BMWi)Duration: 2021-2023

-

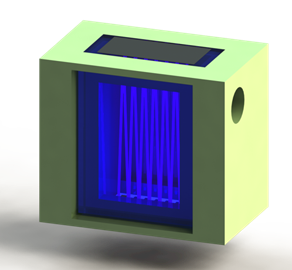

Light-based analytics for the determination of the concentration of chlorine dioxide (LaClO2)As part of the project "Light-based analytics for the determination of the concentration of chlorine dioxide" (LaClO2), a novel sensor for monitoring the chlorine dioxide content of industrial, process and drinking water is being developed and tested.Year: 2017Funding: EFRE (EU)Duration: 2017 - 2019

![]()

![]()

-

Flexible mono- and multi-layer micro-grinding tools for ultra-precision and micro machining of ductile materialsThin-film grinding tools have great potential for the production of high surface qualities and for the production of microstructures. The aim of this project is the fundamental investigation and modelling of the relationships between the manufacturing process and the application behavior of the innovative micro grinding tools.Year: 2017Funding: Deutsche Forschungsgemeinschaft (DFG)Duration: 2017 - 2019

![]()

![]()

-

Tool-integrated temperature measurement for press hardeningAs part of the research project, a tactile thermoresistive temperature sensor based on thin-film technology was developed for use in hot forming. By selecting a suitable base material and designing a sensor contact outside the mechanically stressed area, a negative influence on the component properties could be eliminated. To achieve an economical service life, the sensor surface was provided with a wear protection layer. In addition to the realization of a full control within the scope of quality assurance, the sensors can also contribute to a more economical design of the production process.Year: 2017Funding: AiFDuration: 2014 - 2017

-

Fundamental investigation of the mechanisms of ultrasonic wedge-wedge bonding using varying topographiesUltrasonic wire bonding has been used in microelectronics for more than half a century. However, the underlying mechanisms are not fully understood, which prevents further improvement of this technique. This project’s aim is to find unknown mechanisms and investigate their influence on the bonding process.Year: 2017Funding: Deutsche Forschungsgemeinschaft (DFG)Duration: 2017 - 2019

![]()

![]()

-

Compact atom chip technology for the use in zero-gravity (KACTUS)The goal of the KACTUS project is to further miniaturize and further develop scientific instruments for the generation of Bose-Einstein condensates, a macroscopic quantum object in which the majority of the particles are in the same quantum mechanical state. The particles all have the same wave function and thus form the basis for atom interferometry, in which the wave properties of atoms are analyzed, for example to determine the gravitational constant.Year: 2017Funding: Deutsches Zentrum für Luft- und Raumfahrt (DLR)Duration: 2016 - 2019

![]()

![]()

-

Collaborative project "Light-based analytics for the quantitative determination of chlorine dioxide" (LAClO2)The goal of this cooperation project is the realization of an innovative sensor that can determine the concentration of chlorine dioxide using direct photometric analysis.Year: 2015Duration: 2015 - 2017

![]()

![]()

-

Tactile display for virtual reality applicationsThe research project "Tactile Display for virtual reality applications" includes the conception of a novel tactile display for the simulation of sensory impressions that appeal to haptic perception of stimuli.Year: 2016Funding: Deutsche ForschungsgemeinschaftDuration: 2013 - 2017

![]()

![]()

-

SPP 1337 – Active Microoptics – Subproject: Electromagnetic Triggering of Microoptics: Adaptive Systems Based on Ferrofluid ActuatorsFor this project, the IMPT developed and produced components of thin film technology for a ferrofluid microactuator, which causes the movement of a liquid column and, therefore, causes the displacement of an optical liquid in a micro canal. This leads to the formation of a liquid lens at the end of the canal with a curvature radius and focal length that can be adjusted.Year: 2011Funding: German Research FoundationDuration: 2008-2011

![]()

![]()

-

SFB 516 – A1 – Design of Active Micro SystemsThe aim of the subproject, A1, at IMPT to design and produce, using thin film technology, a microstepping motor which is suitable for fine positioning at the nanometer level.Year: 2011Funding: German Research FoundationDuration: bis 2010

![]()

![]()

-

STUDIUM INITIALE - Transition Management and Integration of Professionally Qualified in Higher EducationSkilled worker shortages and demographic change pose new challenges to the education system. For businesses, it is becoming increasingly difficult to find well-trained workers and to hold on to them.Year: 2014Duration: Oktober 2011 – März 2015

![]()

![]()

-

gebo – T5 – High Temperature Sensors: Pressure Sensor (IMR) and Magnetic Field Sensor (IMPT)Within the framework of the research association, gebo, the Institute of Micro Production Technology (IMPT) is developing a high temperature-capable magnet field sensor for detecting the geomagnetic field in all three spatial directions.Year: 2011Funding: Ministerium für Wissenschaft und Kultur (MWK) + Baker Hughes INTEQ GmbHDuration: 2009 – 2014

![]()

![]()

-

Planar Optronic Systems (PlanOS) - A05The aim of the project is to produce totally polymer-based, large-area sensor networks that can completely do without electronic components.Year: 2014Funding: German Research FoundationDuration: 2013-1017

![]()

![]()

-

BRANDIWithin the framework of the subproject of the project Brandi, the foundations for a packaging technology of a micro-electron source are investigated, which is to be used as an ionization source in non-radioactive, highly sensitive sensor systems for early fire detection.Year: 2014Funding: Federal Ministry of Education and ResearchDuration: 2013-2016

![]()

![]()

-

Hearing for allYear: 2012

-

Integration of Ultrathin Magnetic Field Sensors in Intelligent Automation Components (UltraMag) – Subproject: Development of Ultrathin, Magnetic Field Sensors for Three-Dimensional MeasuringFor this grant project at the IMPT, an ultrathin magnetic field sensor for detecting the state of an electric motor was developed with the goal of optimizing the operation with more sophisticated control algorithms.Year: 2011Funding: Federal Ministry for Education and ResearchDuration: 2009 – 2013

![]()

![]()

-

Micro-MillerAs a part of this project, both mechanical production processes and a combination of lithography and etching processes will be developed and fundamentally researched for the economic batch production of silicon carbide micro cutters.Year: 2014Funding: German Research FoundationDuration: 2014 - 2017

![]()

![]()

-

SFB 653 T14 - Development and manufacturing of direct-deposited sensors on bottom hole assembliesWithin the Collaborative Research Center 653 "Intelligent Components in the Life Cycle" this transfer project has been developed in cooperation with an industrial partner. The aim of the project is the thin-film production of sensitive strain gauges that can detect the mechanical stresses of drilling bottom hole assemblies and withstand the harsh conditions underground. A novel, patent-pending coating system is used for this purpose, which allows sensors to be deposited directly onto component surfaces of any size. In addition to the development of temperature-compensated strain gages, the project also addresses the aspect of deposition on curved surfaces.Year: 2018Funding: DFGDuration: 2018 - 2021

![]()

![]()

-

WInSiC4APThe project “Wide Band Gap Innovative SiC for Advanced Power” (WInSiC4AP) is an international collaborative project funded by the EU ECSEL initiative. More than 20 partners from France, Italy and Germany are jointly developing semiconductor elements and circuits based on silicon carbide (SiC). This semiconductor material is known for its large band gap, which allows transistors to operate at higher voltages and frequencies and also has better efficiency compared to silicon or germanium. Based on such transistors, high-voltage converters for e.g. electromobility, are jointly developed and tested. As a partner in this project, the IMPT is conducting research together with Würth Elektronik on integrated transformers that are integrated within the printed circuit board. These components therefore save space, which then can be used for other electronic components and also allow a height reduction. Conventional inductors and, above all, transformers are often decisive in terms of the space required on a circuit board due to their classic production with wound copper wire. The developed transformers are supposed to be used in gate driver circuits of SiC MOSFETs.Year: 2017Funding: ECSEL (EU)Duration: 2017 - 2021

![]()

![]()

-

Batch manufactured flexible micro-grinding tools for finishing metallic surfacesGrinding tools manufactured by thin-film technology show great potential for the production of high surface finishes and for the manufacture of microstructures. The aim of this project is to investigate and model the relationships between the manufacturing process and the application behavior of the novel, compliant micro-grinding tools. In this context, the technological and economic potential of the lithographically produced tools is also to be identified, especially with regard to batch production. In order to ensure workpiece machining and to demonstrate the tool potential, basic tools with defined parameters will be manufactured according to the requirement profiles of ultra-precision and micro-machining. The characterization of the application behavior of the micro-grinding tools represents a further objective of this project. The main focus is on analyzing the relationships between the abrasive and support layers as well as the application behavior and the manufacturing result. Based on the results of the investigation, an empirical wear model will be developed. Furthermore, the project aims at the development of an electrochemical cell for the oxidation of copper surfaces. This process is intended to control the mechanical properties of the surface in a targeted manner in order to counteract the ductile behavior of the copper during ultraprecision machining and micromachining. This can enable better structuring and higher surface finishes. The cell will also be integrated into a 5-axis CNC milling machine to seamlessly integrate the electrochemical machining of the workpiece into metal-cutting process flows. The oxide behavior of the copper workpieces will also be modeled based on the results. Furthermore, a validation of the models and the tool production will be carried out during the project. Adapted workpieces will then be manufactured and tested on the basis of defined application scenarios.Year: 2019Funding: Deutsche Forschungsgemeinschaft (DFG)Duration: 2019 - 2022

![]()

![]()

-

Magnetic Measurement Advances (MagMA)In the research project Magnetic Measurement Advances (MagMA), the IMPT is developing possible measurement methods and equipment for its industrial partner GlobalFoundries to determine the quality and properties of deposited magnetic layers without the wafers having to leave the production line. Due to the limitations of established measurement methods, the examination of the layers is necessarily performed on separated pieces of the wafer. However, this means that further processing of the wafer is no longer possible, since it can only be processed as a whole. This not only causes considerable additional costs in the development of new layer stacks, but also in the quality assurance of existing systems and processes.Led by: Eike FischerYear: 2021Funding: GlobalFoundriesDuration: 2021 - 2022

![]()

![]()

-

Inner Ear Micro Transducer for the Stimulation of the Perilymph for the Hard of HearingThe goal of the project is to develop an implantable hearing aid (inner ear micro transducer) for restoring hearing by mechanical stimulation of the perilymph in the cochlea. The work is done in collaboration with the Hannover Medical School.Year: 2011Funding: German Research FoundationDuration: 2008-2012

![]()

![]()

-

Research and Development of a High-Resolution Inductive Measurement System (Micro Inductosyn®)This grant project comprises the research, development and production of thin film technology of a miniaturized, high-resolution, inductive displacement measuring system based on the Inductosyn® principle)Year: 2011Funding: German Research FoundationDuration: 2008-2010

![]()

![]()

-

Performance Advances in Recording through Micro ActuationA prerequisite for optimal recording density of hard disk storage is a minimal altitude and a perfect tracking of the read/write head.Year: 2011Funding: European UnionDuration: 2005 - 2009

![]()

![]()

-

Offene Hochschule Niedersachsen (OHN)Within the framework of the “Offene Hochschule Niedersachsen” (OHN), Leibniz Universität Hannover pursues the main goal of making the way easier for the industrially skilled who do not possess a classical university entrance qualification.Year: 2011Funding: Niedersächsischen Ministerium für Wissenschaft und KulturDuration: 2009 - 2012

![]()

![]()

-

FOSTA Research Project (P 1065) – Tool-Integrated Temperature Measurement for Press HardeningThe aim of the research project, “Tool-Integrated Temperature Measurement for Press Hardening,” is temperature measuring in a press hardening tool without affecting the tool properties. The temperature measurement can be in contrast with traditionally used tactile measuring sensors due to the newly developed sensor surface and because the contacting of the sensor can be carried out much more accurately.Year: 2014Duration: 01.09.2014 - 31.08.2016

![]()

![]()

-

Sharpening of Cutting Wheels for Mechanical High-Precision Micro-Machining with Laser RadiationThe mechanical trueing of cutting blades for high-precision machining of brittle materials is carried out with sharpening blocks. During the sharpening, however, approximately two thirds of the blade wear occurs. This project is aimed considerably reducing the blade wear by introducing a laser truing process with the same degree of sharpness.Year: 2011Funding: German Research FoundationDuration: 2010 - 2012

![]()

![]()

-

SFB 516 – B1 – Production of Magnetic Layers for Electromagnetic MicroactuatorsFor the construction of electromagnetic microactuators, soft magnetic and hard magnetic materials are used. In this project, suitable production processes as well as structuring processes of the magnetic layers for the integration in active microsystems were developed.Year: 2011Funding: German Research FoundationDuration: bis 2010

![]()

![]()

-

Magnetoelastic Sensors for the Monitoring of Mechanical Deformations at the Boundary of the Fiber-Matrix in Composite MaterialsA spatial resolution stress and strain sensor system can be created by the use of magnetostrictive materials on carbon fiber surfaces and micro-fine structuring of layers, and it can be used for the electronic monitoring of the load state of safety or service-related fiber compositeYear: 2011Funding: German Research FoundationDuration: 2008 - 2011

![]()

![]()