SFB 653 – L3 – Reading and Writing of Magnetically-Saved Data

| E-Mail: | taptimthong@impt.uni-hannover.de |

| Year: | 2011 |

| Funding: | German Research Foundation |

| Duration: | 2005 - 2017 |

| Is Finished: | yes |

| Further information | http://www.sfb653.uni-hannover.de |

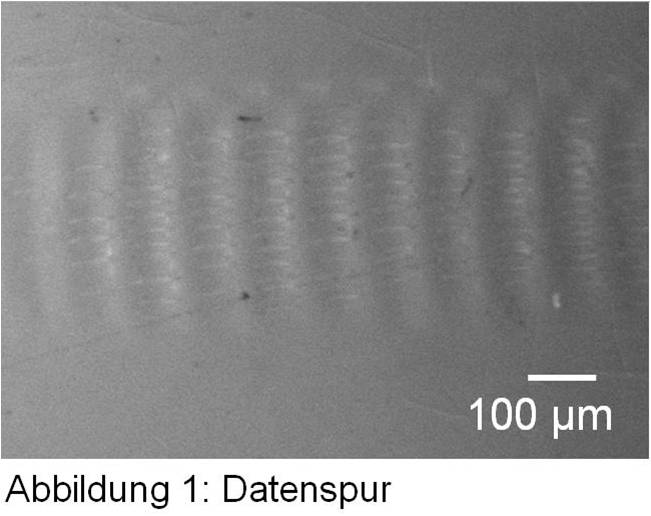

Within the framework of the Collaborative Research Projekt 653 "Gentelligente Bauteile im Lebenszyklus" in subproject L3, a method for magnetic storage of data on the surface of magnetic components in an industrial production environment is being researched. Magnetic (Mg), in which hard magnetic particles (γ-Fe2O3) are embedded in an Mg matrix, is to be used as storage medium. The data is stored inductively with a magnetic write head, which is positioned at a small distance from the sample surface and generates a magnetic data track (Fig. 1). A main goal is a further development of the magnetic write head to achieve high recording densities. For this purpose, the air gap area is modified and its influence is analysed using FEM simulation. For the core part close to the gap, a material with the highest possible saturation flux density is used, such as the AlFeSil or CoFe used in data technology. Two methods are examined for reading out the written data. In the first one, the stored data is read out by field sensors using the anisotropic magnetoresistive effect (AMR) or giant magnetoresistance effect (GMR) (Fig. 2). This method is very well suited for the verification of the written data ("Read-after-Write"). The sensor can be integrated directly into the writing system. The second regular reading method is based on the magneto-optical Kerr effect (MOKE). While the "Read-after-Write" method requires contact between the sensor and the component, the magneto-optical method enables readout at a distance (Fig. 3). For this purpose, a soft magnetic covering layer (keeper layer) is used to reflect the magnetization of the magnetic particles in magnesium. The main objective is to modify the layer properties in such a way that the written bit patterns can be read out with the greatest possible layer thicknesses using MOKE.