SFB 653 – S1 – Modular, Multifunctional Microsensors

| Year: | 2011 |

| Funding: | German Research Foundation |

| Duration: | 2005 - 2017 |

| Is Finished: | yes |

| Further information | http://www.sfb653.uni-hannover.de |

In modern production technology it is necessary to record a large amount of measurement data in order to guarantee process reliability during production and to verify product quality at the end of production. The subproject S1 deals with the development of modular, multi-functional microsensors, which serve to record data relevant to wear, maintenance and recycling during the entire life cycle of a component. The modular design of the microsensors enables process-optimized production of microsensors for measuring force, strain, magnetic properties and temperature. Furthermore, the small dimensions of the microsensors allow universal installation in places that are difficult to access.

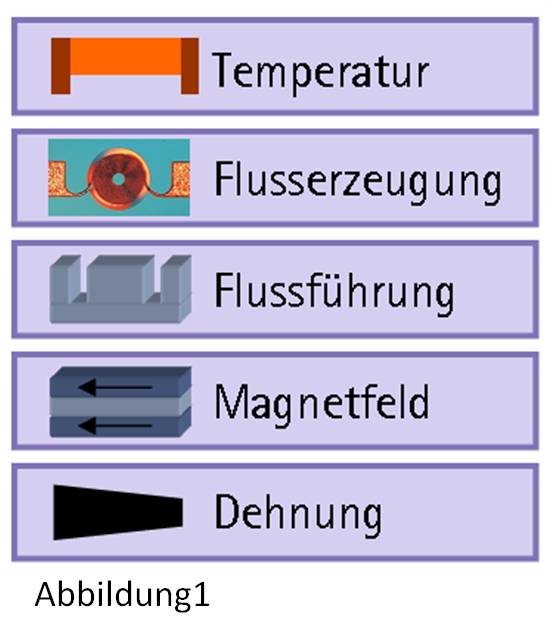

To achieve this goal, the research focus in the first application period was on the development and investigation of functional layers, which were used as elementary basic components of these novel modular microsensors. Fig. 1 shows the components of this modular system. For this purpose, magnetoelastic, magnetoresistive, insulating and temperature-sensitive layers were investigated within the scope of the subproject.

There are special design possibilities when combining different effects. Such a combination allows the realization of a microsensor family that can perform different measuring tasks. Fig. 2 shows the possible combinations of the modular microsensor family. The modular concept was first implemented with the design and characterization of microtemperature, strain and eddy current sensors. Fig. 3 shows a thin film micro temperature sensor.

In the second application period, the main objectives of subproject S1 are to further increase flexibility in the installation of microsensors and to expand the spectrum of microsensors. As before, the demand for microsensors is determined by the other subprojects. The range of applications for these microsensors is to be expanded through improvements in system integration. As in the first application period, the modeling and simulation is carried out by analytical calculations and by using the finite element method (FEM). Subsequently, both microsensors for single use and microsensor arrays are manufactured. After completion of production, the microsensors are subjected to characterization and testing and made available to the user.